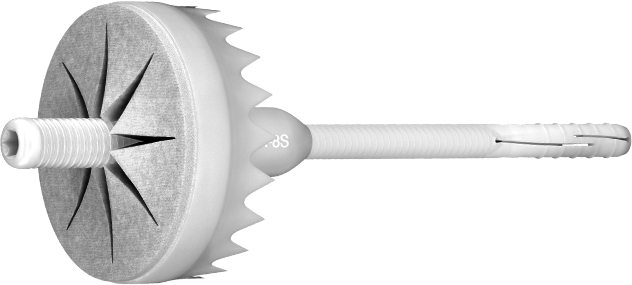

TFIX-8ST UNIVERSAL FACADE FIXINGS

The first thermal insulation combination screw fixing that can be countersunk together with the integrated insulation cap.

Features and benefits

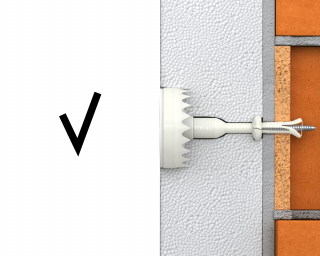

- Accurate countersunk setting automatically sets the fixing flush with the insulation layer

- Integrated insulation cap (with unique surface reinforcement) equalizes thermal conductivity over the fixing point, whilst also leveling out drying times of render.

- Unique sleeve compression zone for precision installations.

- Simple countersunk installation in all substrates (A,B,C,D,E).

- The long plastic overmoulding on the TFIX-8ST screw minimises thermal bridging (value 0.001-0,002W/K), contributing to energy-saving benefits

- The shortest embedment depth at the maximum strength parameters

- Unique design allows for high load-bearing capacities. This reduces the quantity of fixings required per square metre of insulation

- Plate stiffness (value 0.6 kN/mm) ensures smooth elevation surface and stable insulation system.

- Pre-assembled elements of the fixing saves time and labour

Base material

-

Concrete C12/15-C50/60 (Use category A)

-

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

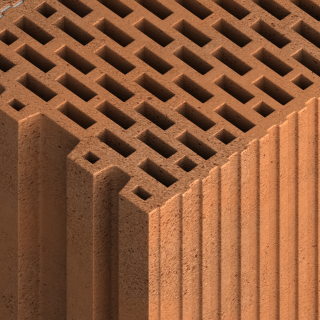

Hollow Brick (Use category C)

-

Hollow Sand-lime Brick (Use category C)

-

Vertically-perforated clay block (Use category C)

-

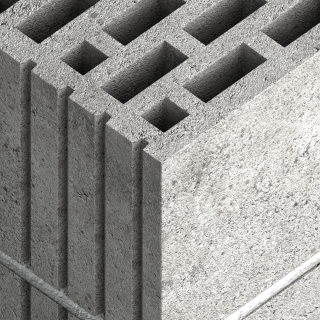

Lightweight Concrete Block (Use category C)

-

Hollow Lightweight Concrete Block (Use category D)

-

.png)

Reinforced components of lightweight aggregate concrete (Use category D)

-

Aerated Concrete Block (Use category D)

Applications

- Polystyrene (EPS) boards

- Mineral wool (MW) boards

- Polyurethane (PU) boards

- External Thermal Insulation Composite Systems (ETICS)

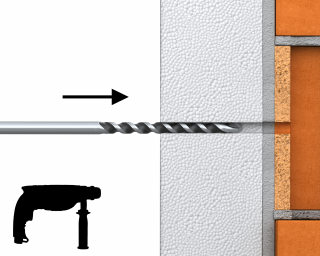

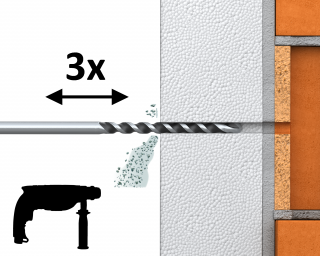

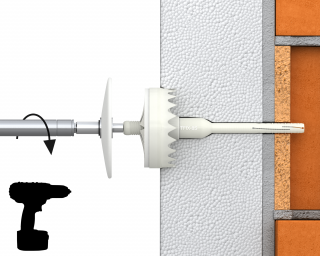

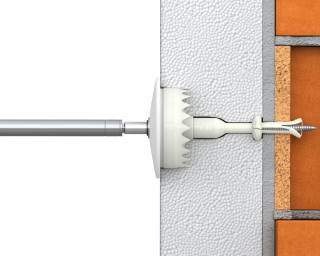

Installation guide

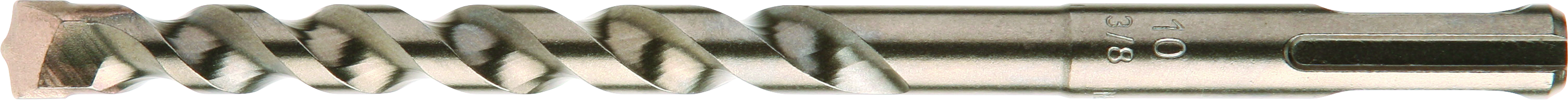

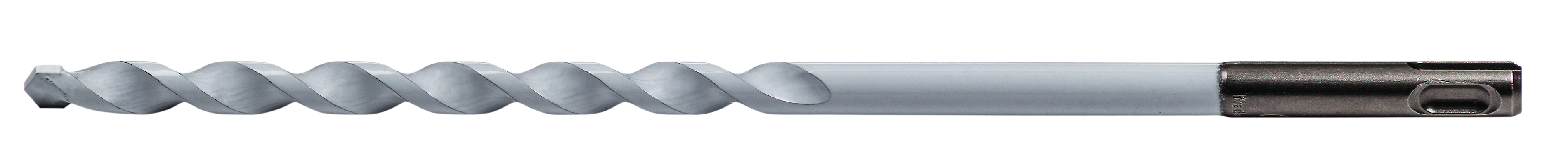

- Drill a hole of required diameter and depth

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in Aerated Concrete Block

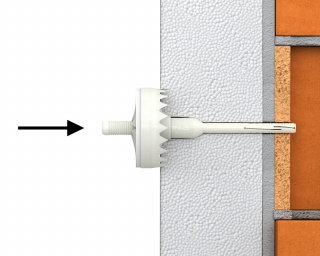

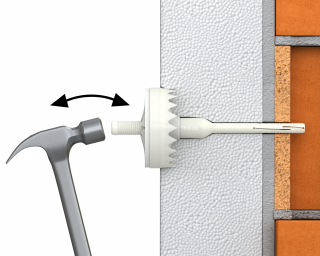

- Lightly tap the plastic sleeve through the insulation material into hole with a hammer, until fixing depth is reached

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block

- When using the KWX-63 the teeth should be embedded in the insulation material after hammering.