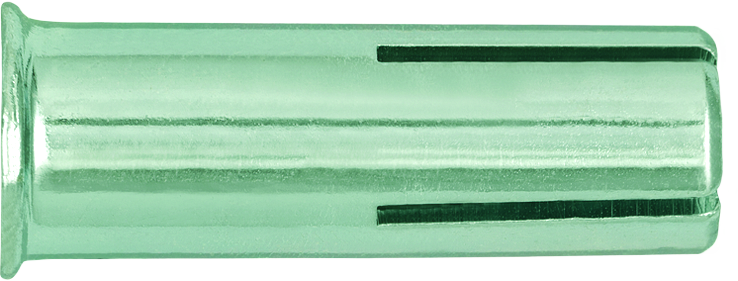

R-DCL Lipped Wedge Anchor

Internally threaded wedge anchor with lip for simple hammer-set installation

Features and benefits

- High performance in cracked and non-cracked concrete confirmed by ETA

- Product is covered with European Technical Assessment for multi-point non-structural fixings

- Product recommended for applications requiring fire resistance

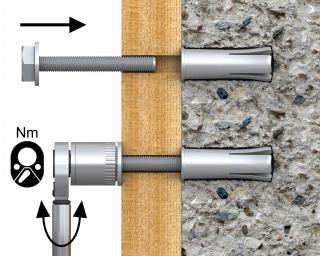

- Internally threaded to be used with threaded stud or bolt

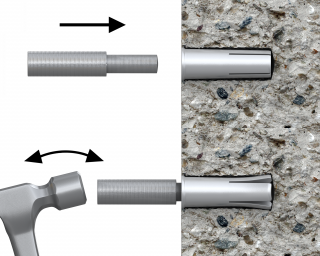

- Easy to install by hammer action and manual setting tool

- Slotted sleeve and internal wedge component together facilitate easy setting and expansion

Product information

Size |

Product Code |

Anchor |

Fixture |

|||

Diameter |

External diameter |

Length |

Internal thread length |

Hole diameter |

||

d |

dnom |

L |

lg |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M6 |

R-DCL-06 |

6 |

8 |

25 |

11 |

7 |

M8 |

R-DCL-08-25 |

8 |

10 |

25 |

14 |

9 |

R-DCL-08 |

8 |

10 |

30 |

14 |

9 |

|

M10 |

R-DCL-10-25 |

10 |

12 |

25 |

14 |

12 |

R-DCL-10 |

10 |

12 |

40 |

19 |

12 |

|

M12 |

R-DCL-12-25 |

12 |

15 |

25 |

14 |

14 |

R-DCL-12 |

12 |

15 |

50 |

25 |

14 |

|

M16 |

R-DCL-16 |

16 |

20 |

65 |

28 |

18 |

Base material

-

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

-

Unreinforced concrete

-

Reinforced concrete

Applications

- Pipelines systems

- Ventilation systems

- Sprinkler systems

- Cable conduits and wires

- Gratings

Installation guide

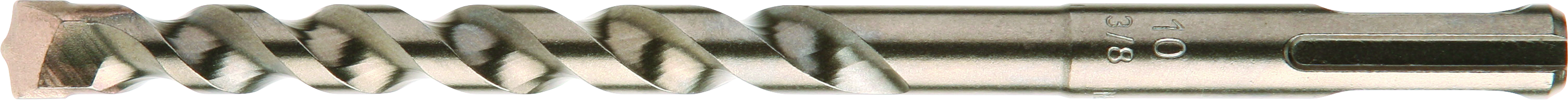

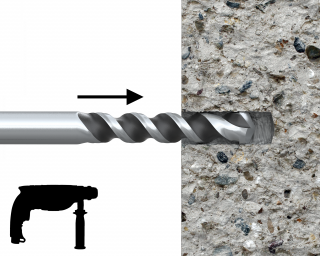

- Drill a hole of required diameter and depth

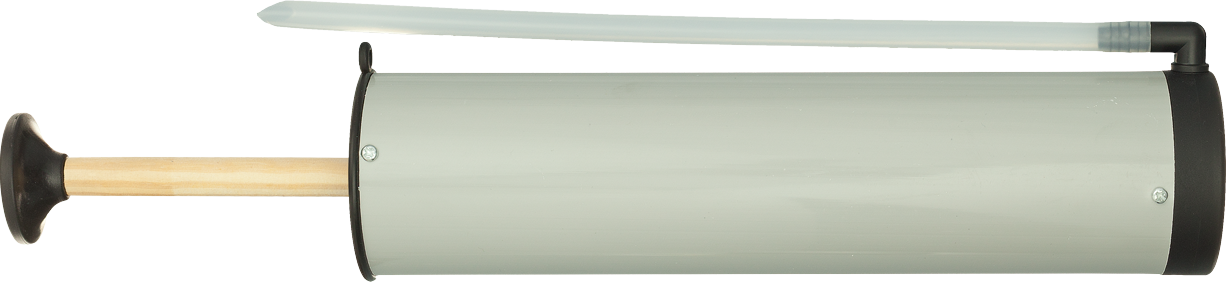

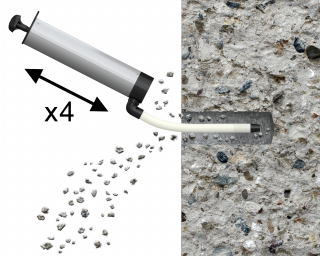

- Remove debris and thoroughly clean hole with pum

- Insert wedge anchor, slotted end first

- Use the setting tool to drive the internal wedge into the anchor

- Insert bolt or stud through fixture and tighten to the recommended torque

Installation data

Normal concrete

Size |

M6 |

M8/25 |

M8 |

M10/25 |

M10 |

M12/25 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

6 |

8 |

8 |

10 |

10 |

12 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

8 |

10 |

10 |

12 |

12 |

15 |

15 |

20 |

Max. installation torque |

Tinst |

[Nm] |

4.5 |

11 |

11 |

22 |

22 |

38 |

38 |

98 |

Min. hole depth in substrate |

h0 |

[mm] |

27 |

27 |

32 |

27 |

42 |

27 |

52 |

67 |

Min. installation depth |

hnom |

[mm] |

25 |

25 |

30 |

25 |

40 |

25 |

50 |

65 |

Min. substrate thickness |

hmin |

[mm] |

80 |

80 |

80 |

80 |

80 |

80 |

100 |

130 |

Min. spacing |

smin |

[mm] |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

260 |

Min. edge distance |

cmin |

[mm] |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

195 |

Hollow concrete slab

Size |

M6 |

M8/25 |

M8 |

M10/25 |

M10 |

M12/25 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

6 |

8 |

8 |

10 |

10 |

12 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

8 |

10 |

10 |

12 |

12 |

15 |

15 |

20 |

Max. installation torque |

Tinst |

[Nm] |

4.5 |

11 |

11 |

22 |

22 |

38 |

38 |

98 |

Min. hole depth in substrate |

h0 |

[mm] |

27 |

27 |

32 |

27 |

42 |

27 |

52 |

67 |

Min. installation depth |

hnom |

[mm] |

25 |

25 |

30 |

25 |

40 |

25 |

50 |

65 |

Min. substrate thickness |

hmin |

[mm] |

80 |

80 |

80 |

80 |

80 |

80 |

100 |

130 |

Min. spacing |

smin |

[mm] |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

260 |

Min. edge distance |

cmin |

[mm] |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

195 |