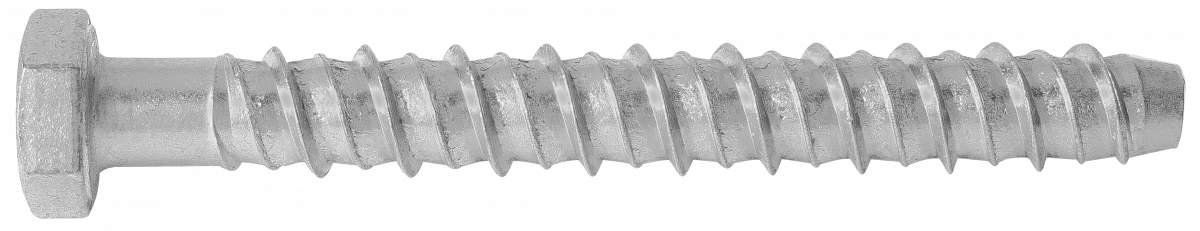

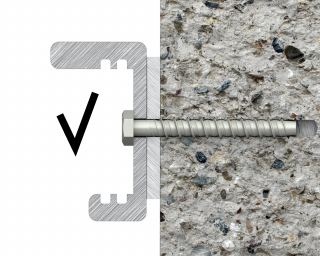

R-LX-H-ZF Zinc flake coated Hex Concrete Screw Anchor

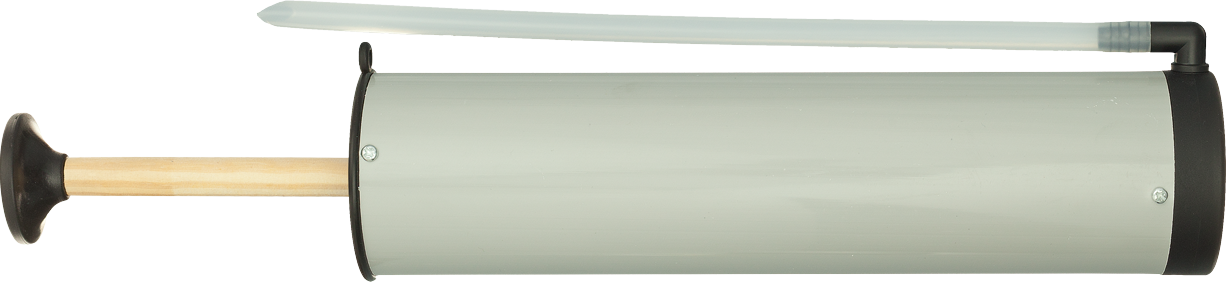

Self-tapping concrete screwbolt

Features and benefits

- Time-efficient through-fixing installation with streamlined procedure - simply drill and drive.

- Completely removable with possibility of reuse

- Non-expansion functioning ensures low risk of damage to base material and makes R-LX ideal for installation near edges and adjacent anchors

- Unique design with patented threadform ensures high performance for relatively small hole diameter

- Special zinc flake corrosion-resistant coating

- High performance in both uncracked and cracked concrete

- Different head types for any application

- Oversize head for fixtures with elongated holes

- Excellent product for temporary fixing

- Suitable for standard and reduced embedment depth

Product information

Size |

Product Code |

Anchor |

Fixture |

|||

Diameter |

Length |

Max. thickness tfix for: |

Hole diameter |

|||

d |

L |

hnom,red |

hnom,std |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

8 |

R-LX-08X060-H-ZF |

10 |

60 |

10 |

- |

12 |

R-LX-08X075-H-ZF |

10 |

75 |

25 |

5 |

12 |

|

R-LX-08X090-H-ZF |

10 |

90 |

40 |

20 |

12 |

|

R-LX-08X100-H-ZF |

10 |

100 |

50 |

30 |

12 |

|

R-LX-08X130-H-ZF |

10 |

130 |

80 |

60 |

12 |

|

R-LX-08X150-H-ZF |

10 |

150 |

100 |

80 |

12 |

|

10 |

R-LX-10X065-H-ZF |

12.5 |

65 |

10 |

- |

14 |

R-LX-10X075-H-ZF |

12.5 |

75 |

20 |

- |

14 |

|

R-LX-10X085-H-ZF |

12.5 |

85 |

30 |

- |

14 |

|

R-LX-10X100-H-ZF |

12.5 |

100 |

45 |

15 |

14 |

|

R-LX-10X120-H-ZF |

12.5 |

120 |

65 |

35 |

14 |

|

R-LX-10X140-H-ZF |

12.5 |

140 |

85 |

55 |

14 |

|

14 |

R-LX-14X105-H-ZF |

17 |

105 |

30 |

- |

18 |

R-LX-14X135-H-ZF |

17 |

135 |

60 |

15 |

18 |

|

For use also with

-

Concrete

-

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

-

Reinforced concrete

-

Unreinforced concrete

-

Natural Stone (after site testing)

Applications

- Through-fixing

- Temporary anchorages

- Formwork support systems

- Balustrading & handrails

- Fencing & gates manufacturing and installation

- Racking systems

- Public seating

- Scaffolding

Installation guide

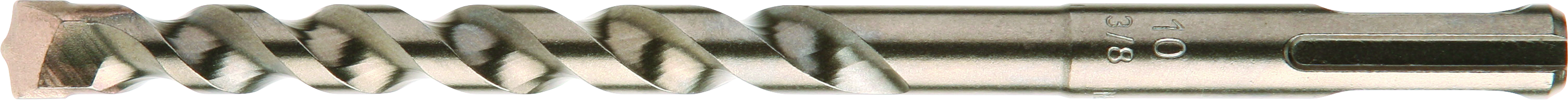

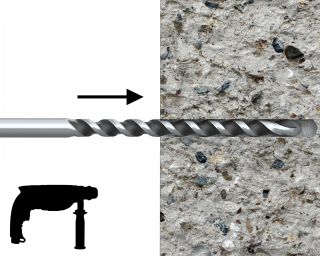

- Drill the hole with rotary hammer drilling machine. Drill to a required depth.

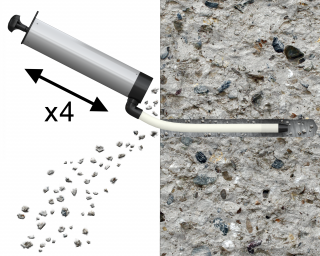

- Blow out dust at least 4 times with a hand pump.

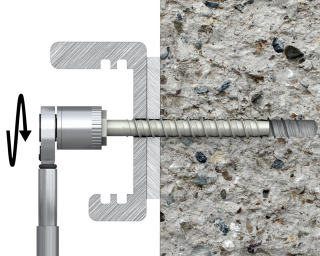

- Possibility of unscrewing and re-screwing.

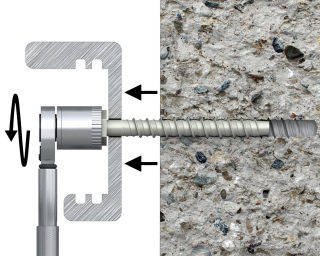

- Tighten to the recommended torque.

- After installation.

Installation data

Size |

8 |

10 |

14 |

||

Thread diameter |

d |

[mm] |

9.9 |

12.4 |

17.4 |

Hole diameter in substrate |

d0 |

[mm] |

8 |

10 |

14 |

Wrench size |

Sw |

[mm] |

15 |

17 |

22 |

Max. installation torque |

Tinst |

[Nm] |

40 |

- |

- |

Max. torque for impact screw driver |

Timp,max |

[Nm] |

900 |

950 |

950 |

STANDARD EMBEDMENT DEPTH | |||||

Real hole depth in substrate |

h0 |

[mm] |

L + 10 - tfix |

L + 10 - tfix |

L + 10 - tfix |

Min. installation depth |

hnom,s |

[mm] |

70 |

85 |

120 |

Min. substrate thickness |

hmin,s |

[mm] |

110 |

130 |

190 |

Min. spacing |

smin, s |

[mm] |

50 |

60 |

100 |

Min. edge distance |

cmin, s |

[mm] |

50 |

60 |

100 |

REDUCED EMBEDMENT DEPTH | |||||

Min. hole depth in substrate |

h0,r |

[mm] |

60 |

65 |

85 |

Real hole depth in substrate |

h0 |

[mm] |

L + 10 - tfix |

L + 10 - tfix |

L + 10 - tfix |

Min. installation depth |

hnom,r |

[mm] |

50 |

55 |

75 |

Min. substrate thickness |

hmin,r |

[mm] |

100 |

100 |

110 |

Min. spacing |

smin,r |

[mm] |

50 |

60 |

100 |

Min. edge distance |

cmin,r |

[mm] |

50 |

60 |

100 |

STANDARD EMBEDMENT DEPTH | |||||

Min. hole depth in substrate |

h0,s |

[mm] |

- |

95 |

130 |