R-SL-FIX-HIGH Advanced hybrid polymer grab adhesive

Features and benefits

- Instant high initial tack: 500 kg/m2 on a vertical surface, 125 kg/m2 on a horizontal surface

- Joint perfectly bonds materials that undergo thermal and mechanical stresses

- Excellent adhesion to common construction materials

- Solvent and isocyanates free - can be painted

- Can be applied on wet substrates

- Odorless, insensitive to chemicals - weak acids, alkalis, solvents and oils

- Can be painted after curing (including water paints)

- Joint is completely resistant to changing weather conditions

Base material

-

Concrete

-

Wood

-

Oriented Strand Board

-

Plaster

-

Cork

-

High-Density Natural Stone

-

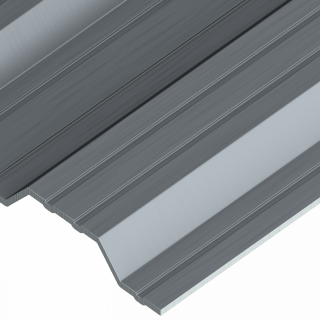

Metal Sheet & Profiles

-

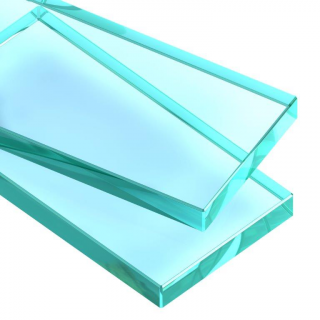

Glass

-

Ceramics

-

Protected metals (aluminium, brass, copper, steel, zinc-plated metal sheet)

-

boards_WebRes.png)

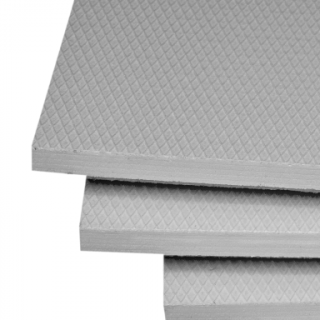

Polystyrene (EPS) Boards

-

XPS Extruded Polystyrene Insulation Boards

-

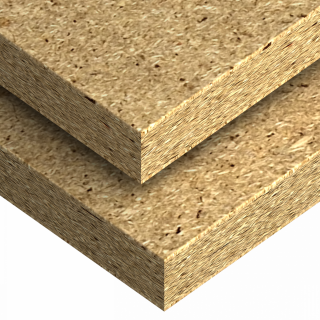

Chipboard

-

Solid Brick

Applications

- Bonding of heavy loaded elements: window sills, frames, masking frames, shelves, panels

- Gluing to smooth and porous surfaces

- Bonding and sealing of many construction materials such as natural stone, wood, concrete, metal, brick, glass, mirrors, ceramics, plaster, polyurethane, plastics, chipboards, etc.

- The connections between galvanized steel, brass and other metals.

Installation guide

- The surface, that adhesive will be apllied on, should be clean, free of dust, grease, rust, remains of old seal and other substances that might weaken the cohesion.

- Prior to application of adhesive protect edges with masking tape.

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Place the cartridge in the extruding gun and apply the adhesive with manual or pneumatic gun.

- Applied glue may be smoothed with a spatula or similar tool. Moisten the spatula first in special wetting agent or detergent solution.

- The adhesive hardens by reaction with moisture from the air, so ensure well-ventilated conditions.

- After completing the application, wipe tools with a paper towel and clean with solvent.