R-SL-FIX-SBS Mounting Adhesive SBS

Mounting Adhesive SBS - universal with very good adhesion. Recommended for mounting and finishing works.

Features and benefits

- Very good adhesion to wood, MDF, HDF, concrete, plaster, brick, metal, glass, hard PVC, and the most common materials in the building industry

- High bonding strength

- Remains flexible after hardening

- Ideal for renovations and finishing works

- Fast curing and effective penetration of the substrate

Base material

-

Concrete

-

Masonry

-

Wood

-

Plasterboard

-

Oriented Strand Board

-

High-Density Natural Stone

-

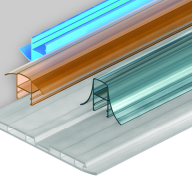

PVC Profile

-

Glass

For use also with

-

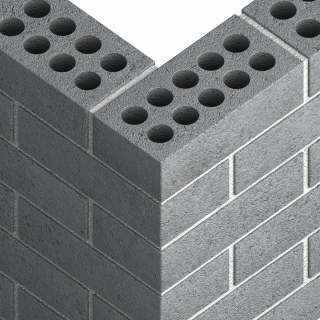

Solid Concrete Block

-

Hollow-core Slab

-

Concrete Slab

-

.png)

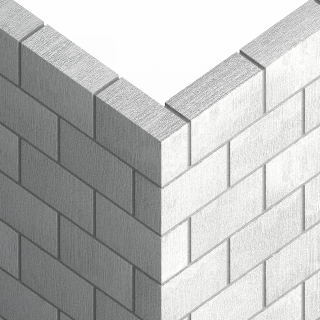

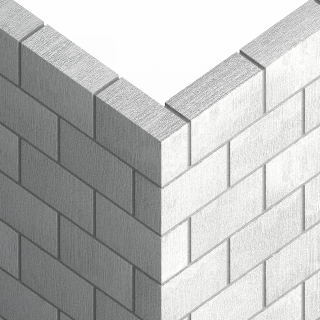

Aerated Concrete Block

-

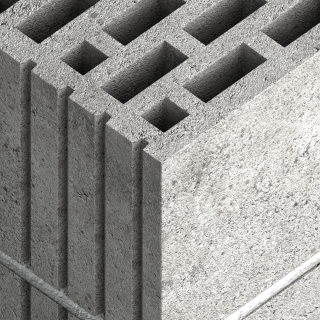

Lightweight Concrete Block

-

Hollow Lightweight Concrete Block

-

Silicate Blocks

-

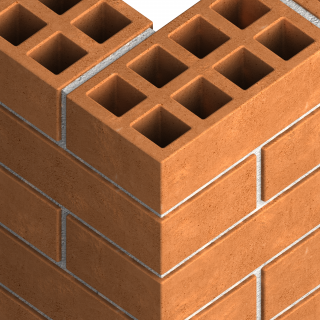

Hollow Brick

-

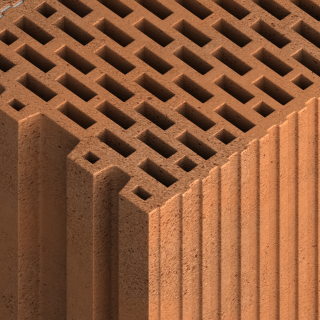

Vertically-perforated Clay Block

-

Hollow Sand-lime Brick

-

Solid Brick

-

Solid Sand-lime Brick

-

Ceramic Hollow Block

-

Gypsum Fibreboards

-

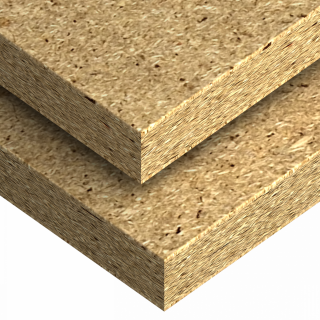

Chipboard

-

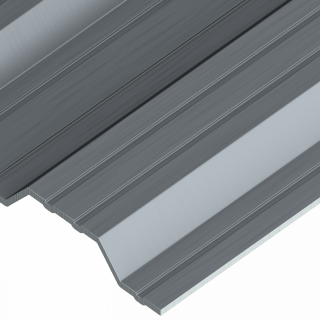

Metal Sheet & Profiles

Applications

- Installation of panels, profiles, moldings and wall skirtings.

- Bonding of window sills, plafonds, stone and ceramic tiles.

- Fixing of doorsteps, stairs and cornices.

- Should not be applied on styrofoam.

Installation guide

- The surface, that adhesive will be apllied on, should be clean, free of dust, grease, rust, remains of old seal and other substances that might weaken the cohesion.

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Place the cartridge in the extruding gun and apply the adhesive with manual or pneumatic gun.

- Apply drops or strips of adhesive on the glued surface and spread thoroughly. Join the surfaces and disconnect. Wait 5 minutes. stick together again and press firmly.

- The joint achieves its ultimate strength in 1-7 days, dependingly on the type of material, layer thickness and conditions. The placement of the glued piece can be amended only by move it witout disconnecting.

- After completing the application, wipe tools with a paper towel and clean with solvent.