R-SL-MA-FAST Light Fast Acrylic

Acrylic dispersion sealant

Features and benefits

- Perfect adhesion to the most building materials (including porous)

- No shrinkage - can be applied with a thin layer without the risk of shrinkage and cracking

- Easy and fast application and work- filling, smoothing and polishing seals

- No need to use Anti-Scratch Tape

- Dust-free grinding

- For interior use

Base material

-

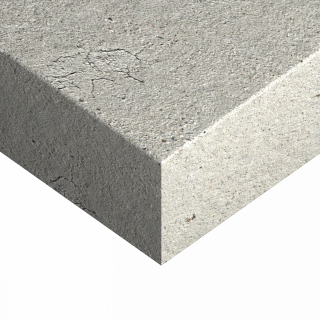

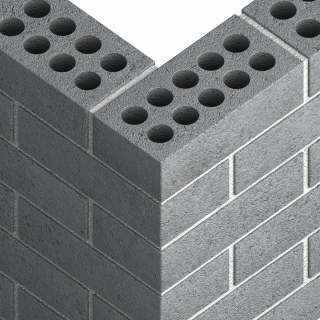

Concrete

-

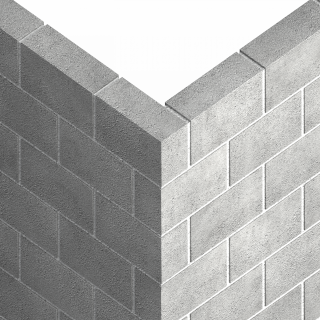

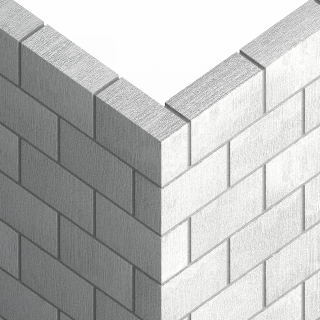

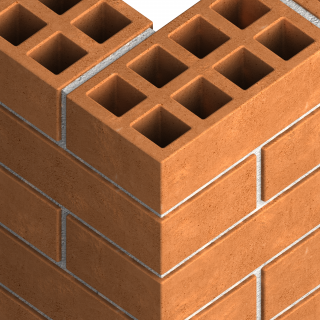

Masonry

-

Wood

-

Plasterboard

-

Oriented Strand Board

-

High-Density Natural Stone

-

Plaster

For use also with

-

Solid Concrete Block

-

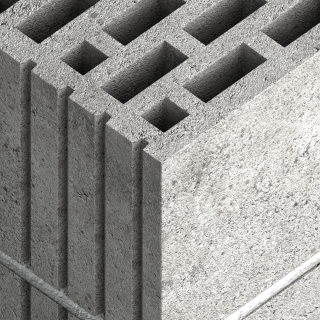

Hollow-core Slab

-

Concrete Slab

-

.png)

Aerated Concrete Block

-

Hollow Lightweight Concrete Block

-

Silicate Blocks

-

Hollow Brick

-

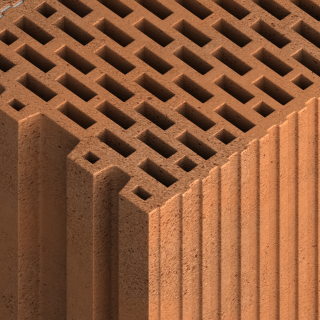

Vertically-perforated Clay Block

-

Hollow Sand-lime Brick

-

Solid Brick

-

Solid Sand-lime Brick

-

Ceramic Hollow Block

-

Gypsum Fibreboards

-

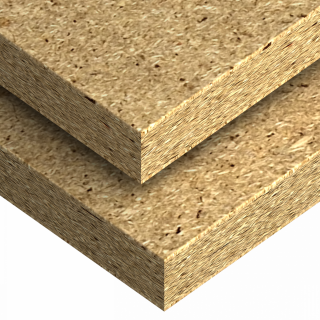

Chipboard

-

Oriented Strand Board

-

Stainless Steel

Applications

- Filling cracks in walls and ceilings

- Fast repair defects in cracks - can be sanded and painted 20 min after application

- Grouting connections joints of drywall boards

- Covering screw heads & bolts

- Filling joints during installation of partition walls and suspended ceilings

Installation guide

- Clean up the gap. Surface, that the acrylic will be applied on, should be clean, free of dust, dirt, grease, oil, rust, remains of old sealant and other substances that might lower the cohesion.

- In case of absorptive substrates, the priming is suggested. The test of adhesion prior application is also recommended.

- Prior to application, protect edges with masking tape

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Use manual or pneumatic gun applicator.

- The applied acrylic can be smoothed with a spatula.

- After completing the application, wipe tools with a paper towel and wash with water.

- Fully dried product should be secured with plaster, paint etc.