R-SL-SAN Sanitary Silicone

Sanitary silicone – One-component, elastic sealant with acetate curing system

Features and benefits

- Highly and permanently elastic sealing properties, with excellent resistance to water, grease, acids and alkalis.

- Protects against the growth of fungi and mould

- Very good adhesion to materials and substrates used commonly in construction: glass, tiles, ceramics and protected metals

- Durable seal (completely resistant to weathering and UV radiation)

Base material

-

Glass

-

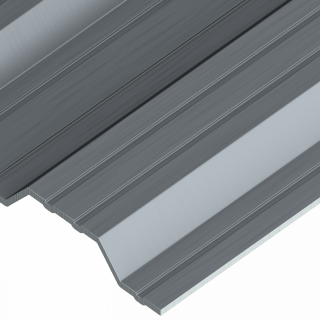

Protected metals (aluminium, brass, copper, steel, zinc-plated metal sheet)

-

Terracotta

-

Ceramics

-

Glaze

-

Protected wood

-

Sanitary ceramics

Applications

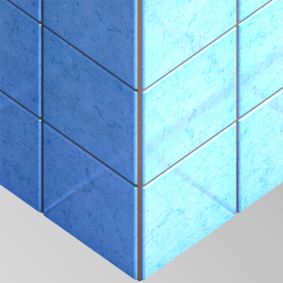

- Sealing in areas with exposure to water: bathrooms, baths (incl. acrylic bathtubs), shower trays, shower enclosures and washbasins, as well as kitchens, laundries, sinks and worktops, etc.

- Do not use for fish tanks, mirrors, unprotected metals, natural stone or concrete.

- Sealing in areas with exposure to sea water: swimming pools, boats, port facilities, etc.

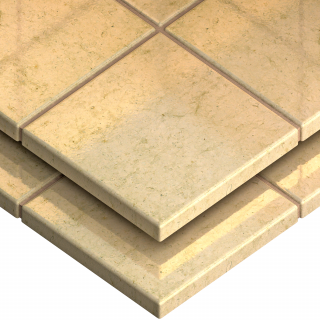

- Sealing of joints between sanitary ceramics and tiles.

- Sealing of worktops.

Installation guide

- The surface, that silicone will be apllied on, should be clean, free of dust, grease, rust, remains of old seal and other substances that might weaken the cohesion.

- Prior to application of silicone protect edges with masking tape

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Use manual or pneumatic gun applicator.

- Applied silicone may be smoothed with a spatula or similar tool. Moisten the spatula first in special wetting agent or detergent solution.

- The silicone hardens by reaction with moisture from the air, so ensure well-ventilated conditions.

- After completing the application, wipe tools with a paper towel and clean with solvent.