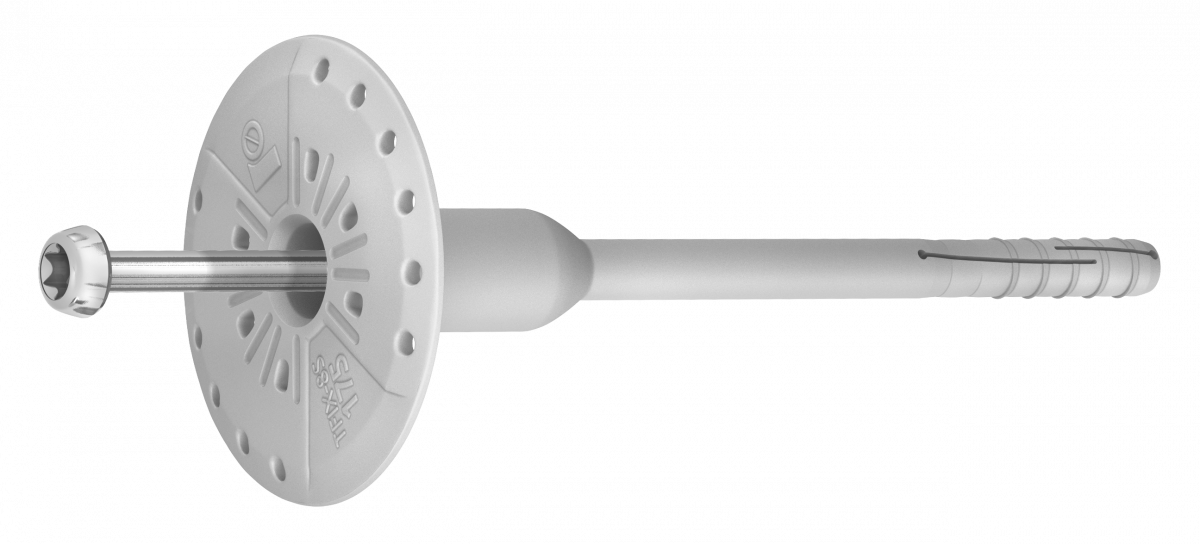

R-TFIX-8S-...-X Universal facade fixing with plain screw

The most effective screw-in facade fixing for countersunk installation with the possibility of surface mounting

Technical Data Sheet

R-TFIX-8S-...-X Universal facade fixing with plain screw - Technical Data SheetFeatures and benefits

- Quick and easy installation in all substrates (categories A,B,C,D,E)

- Unique sleeve compression zone for precision installations.

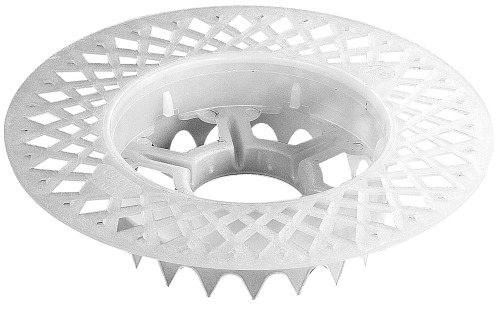

- Installation with post-installed insulation cap R-TFIX-CAP63 in three versions: R-TFIX-CAP63-EPS-W, R-TFIX-CAP63-EPS-G, R-TFIX-CAP63-EPS-MW reduces heat transmission and results in a homogenous insulation surface

- Plate stiffness (value 0.6 kN/mm) ensures smooth elevation surface and stable insulation system.

- Unique design allows for high load-bearing capacities. This reduces the quantity of fixings required per square metre of insulation

- The shortest embedment depth at the maximum strength parameters

- Countersunk installation possible with use of R-TFIX-TOOL-CS or additional R-KWX-063 plate with post-installed R-TFIX-CAP63 insulation cap and system bit R-TFIX-TOOL-BLACK

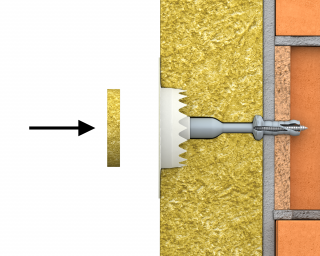

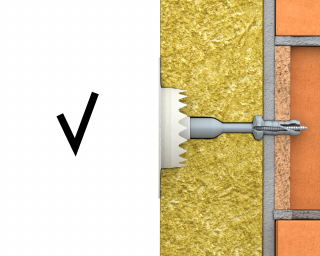

- Installation flush with the surface possible with use of R-TFIX-TOOL-BLACK system bit and post-installed R-TFIX-CAP15 insulation cap

- Pre-assembled screw saves time and labour

Product information

Size |

Product Code |

Fixing |

Fixture |

|||

Diameter |

Plate diameter |

Length |

Recommended thickness |

|||

d |

D |

L |

tfix A, B, C, D |

tfix E |

||

[mm] | ||||||

Ø08 |

R-TFIX-8S-115-X |

8 |

60 |

115 |

80 |

40 |

R-TFIX-8S-135-X |

8 |

60 |

135 |

100 |

60 |

|

R-TFIX-8S-155-X |

8 |

60 |

155 |

120 |

80 |

|

R-TFIX-8S-175-X |

8 |

60 |

175 |

140 |

100 |

|

R-TFIX-8S-195-X |

8 |

60 |

195 |

160 |

120 |

|

R-TFIX-8S-215-X |

8 |

60 |

215 |

180 |

140 |

|

R-TFIX-8S-235-X |

8 |

60 |

235 |

200 |

160 |

|

R-TFIX-8S-255-X |

8 |

60 |

255 |

220 |

180 |

|

R-TFIX-8S-275-X |

8 |

60 |

275 |

240 |

200 |

|

R-TFIX-8S-295-X |

8 |

60 |

295 |

260 |

220 |

|

R-TFIX-8S-335-X |

8 |

60 |

335 |

300 |

260 |

|

R-TFIX-8S-355-X |

8 |

60 |

355 |

320 |

280 |

|

R-TFIX-8S-375-X |

8 |

60 |

375 |

340 |

300 |

|

R-TFIX-8S-395-X |

8 |

60 |

395 |

360 |

320 |

|

R-TFIX-8S-415-X |

8 |

60 |

415 |

380 |

340 |

|

R-TFIX-8S-435-X |

8 |

60 |

435 |

400 |

360 |

|

R-TFIX-8S-455-X |

8 |

60 |

455 |

420 |

380 |

|

R-TFIX-8S-315-X |

8 |

60 |

315 |

280 |

250 |

|

Base material

-

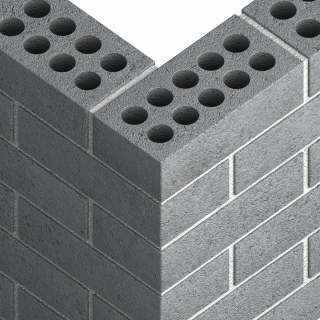

Concrete C12/15-C50/60 (Use category A)

-

Concrete External wall panel C 16_20 – C50_60_1.png)

External wall panel of concrete C16/20 – C50/60 (Use category A)

-

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

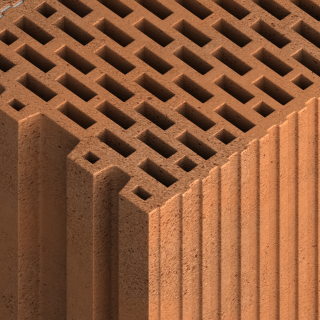

Hollow Brick (Use category C)

-

Hollow Sand-lime Brick (Use category C)

-

Vertically-perforated clay block (Use category C)

-

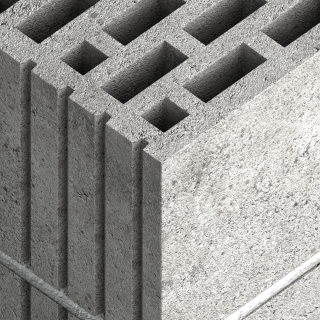

Lightweight Concrete Block (Use category C)

-

Hollow Lightweight Concrete Block (Use category D)

-

.png)

Reinforced components of lightweight aggregate concrete (Use category D)

-

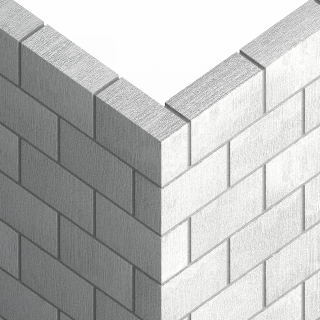

Autoclaved Aerated Concrete (Use Category E)

Applications

- External Thermal Insulation Composite Systems (ETICS)

- Polystyrene (EPS) boards

- Polyurethane (PU) boards

- Mineral wool (MW) boards

- Cork boards

- Lightweight wood wool building boards

Installation guide

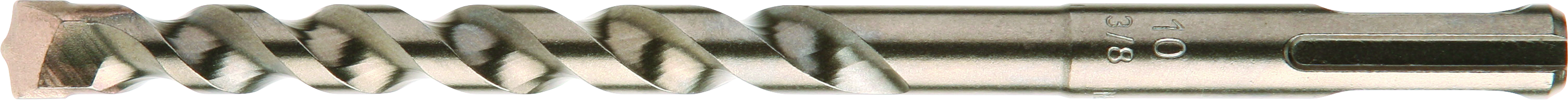

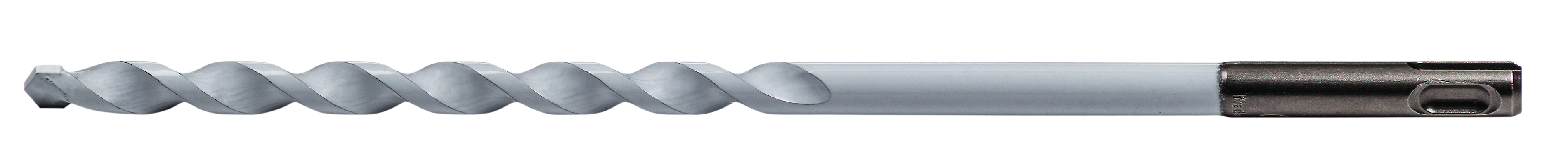

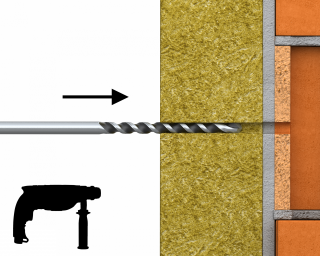

- Drill a hole of required diameter and depth

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in Aerated Concrete Block.

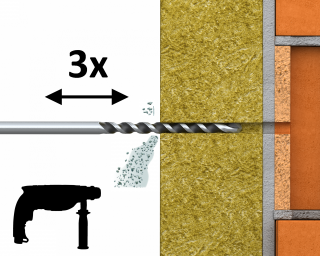

- Clean drilled hole 3 times.

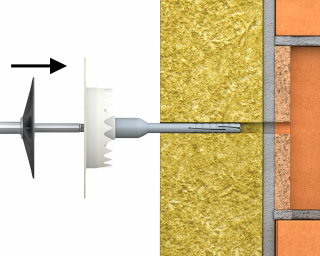

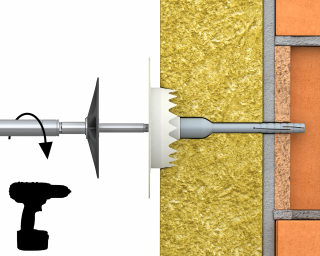

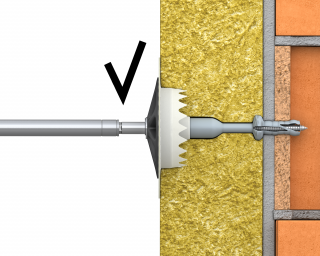

- Insert R-TFIX-TOOL-BLACK into recess in head moulding of R-TFIX-8SX screw.

- Insert the fixing into the drilled hole.

- When using the KWX-63 the teeth should be embedded in the insulation material after hammering.

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block.

- Apply steady axial pressure, ensuring the disc of the setting tool is kept perpendicular to the fixing axis.

- Steadily drive in the screw with high revs until fixing is secure (when disc touches insulation surface).

Installation data

Substrate |

A, B, C, D |

A - external panel |

E |

||

Hole diameter in substrate |

d0 |

[mm] |

8 |

8 |

8 |

Min. installation depth |

hnom |

[mm] |

25 |

25 |

45 |

Min. hole depth in substrate |

h0 |

[mm] |

35 |

35 |

55 |

Min. hole depth in substrate - countersunk mounting |

h0 |

[mm] |

45 |

45 |

65 |

Min. substrate thickness |

hmin |

[mm] |

100 |

40 |

100 |

Min. spacing |

smin |

[mm] |

100 |

100 |

100 |

Min. edge distance |

cmin |

[mm] |

100 |

100 |

100 |

Fixing diameter |

d |

[mm] |

8 |

8 |

8 |

Downloads

- R-TFIX-8S-...-X Universal facade fixing with plain screw - Technical Data Sheet

- UKTA_R-TFIX-8S_0836-22_6348_2022_EN.pdf

Need documents for other product? Visit our Technical Library.

go to library