RPP-B1 Fire Resistant Foam

B1 - Low-pressure, one-component polyurethane fire-resistant foam with applicator gun.

Features and benefits

- Fire-resistant - EI 240 fire resistance, providing technical approval criteria are fulfilled

- Insulates against fire, smoke and gas

- Self-extinguishing.

- Ideal for mounting, sealing and soundproofing.

- Cutting time 40 min after apllication

- Can be painted or plastered when cured

- Excellent adhesion to most materials and substrates used in construction.

- Yield up to 45 l

- Resistant to mould and fungi.

Base material

-

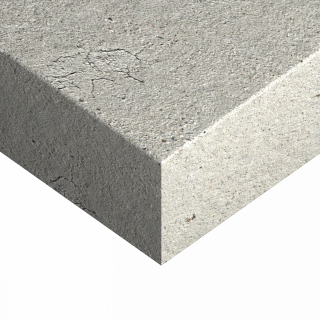

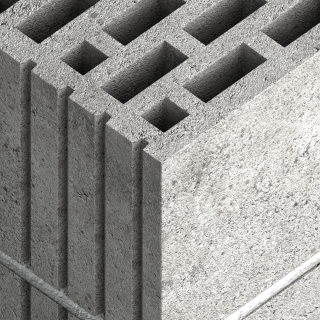

Concrete

-

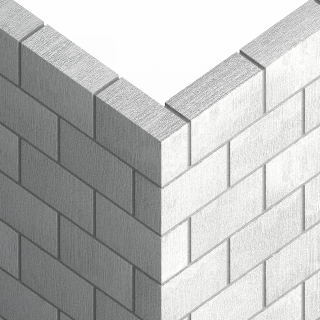

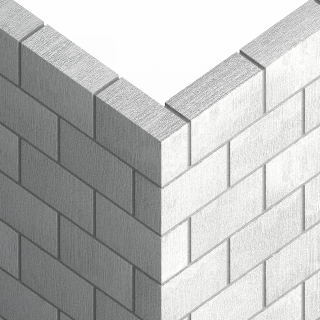

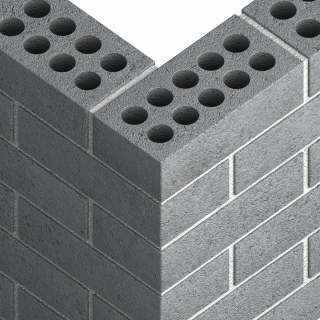

Solid Concrete Block

-

.png)

Aerated Concrete Block

-

Masonry

-

Stainless Steel

-

Wood

-

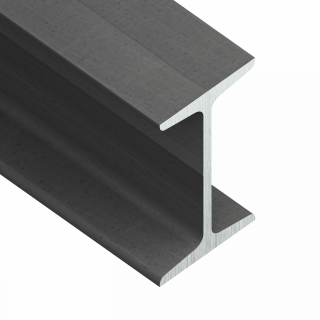

Aluminium

-

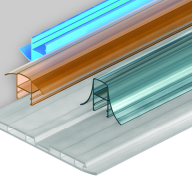

PVC Profile

-

Window Profile

For use also with

-

Concrete Slab

-

Gypsum Fibreboards

-

Silicate Blocks

-

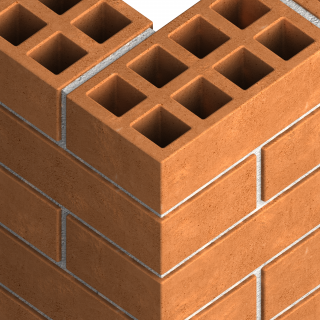

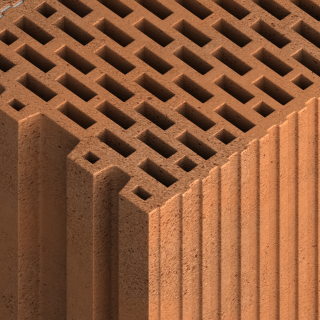

Ceramic Hollow Block

-

High-Density Natural Stone

-

Hollow Lightweight Concrete Block

-

Lightweight Concrete Block

-

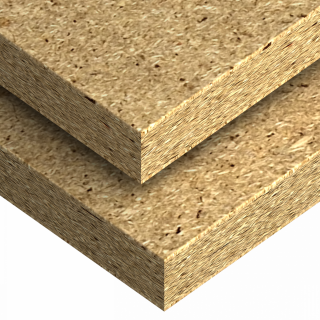

Chipboard

-

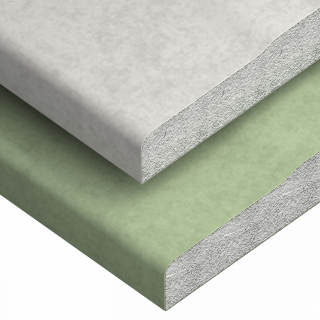

Plasterboard

-

Solid Brick

-

Solid Sand-lime Brick

-

Hollow Sand-lime Brick

-

Hollow Brick

-

Vertically-perforated Clay Block

Applications

- For all applications with a legal requirement for fire resistance class B-1 according to DIN 4102

- For all applications where the increased fire resistance according to PN EN 1366-4 is required:- Bonding insulation materials- Creation of soundproof screens with increased fire resistance- Insulation around cables and pipes- Sealing joints in roofs construction

- For fireproof assembly of PVC, wood and aluminum frames.

- For fire-resistant sealing of joints in roofing, walls and ceilings.

- For fire-resistant filling of frame structures

Installation guide

- Wear protective gloves. Ensure surfaces are free from dust, dirt or debris.

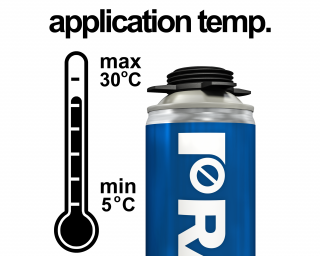

- Before using, make sure that the can temperature is above zero (optimum +20°C). Application temperature from +5°C up to +30°C.

- Shake can vigorously for 30 seconds to mix properly components.

- Screw gun onto the can. Hold can upside-down during application.

- Moisten surfaces with water prior to application.

- Fill gaps from down to up, zigzag motion, alternating from one wall to the other. Fill gaps to approximately 60 % volume. Max. wide of the gap 3-4 cm. Wider gaps should be applied after hardening of the previous layer. Each layer should be moistened with water using a spray.

- After full curing, cut the excess foam with a knife and protect it from UV exposure by coating with plaster, paint, acrylic or silicone.

- In the event of a stoppage exceeding five minutes duration, wipe the nozzle with cleaner for foam applicator.

- After removing the applicator gun from the can, wipe down the nozzle and gun (internal and external surfaces) using a cleaner.

Downloads

- RPP-B1 Fire Resistant Foam - Technical Data Sheet

- ETA 13 1076 - Fomoheat - Penetrations_EN.pdf

- ETA 13 1075 - Fomoheat - Linear Gaps_EN.pdf

Need documents for other product? Visit our Technical Library.

go to library