RPP-FIX-60S Express polyurethane adhesive

Professional fast foam adhesive with high adhesion to many materials and substrates

Features and benefits

- Initial tack after 60 seconds

- Mechanical anchoring after 2h

- Complete hardening time after 24h

- Wide range of applications

- Excellent adhesion to common construction materials

- Easy and convenient application

For use also with

-

boards_WebRes.png)

Polystyrene (EPS) Boards

-

Plasterboard

-

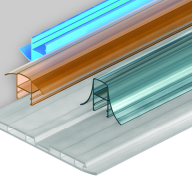

PVC Profile

-

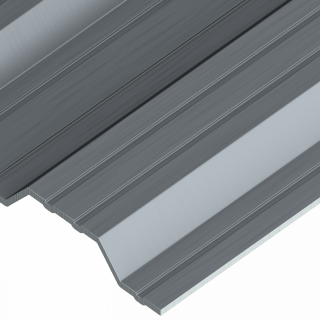

Metal Sheet & Profiles

-

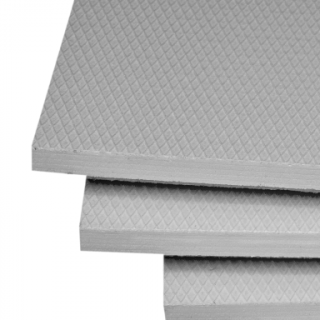

XPS Extruded Polystyrene Insulation Boards

-

Oriented Strand Board

-

Mineral Wool Boards

-

Timber

-

Solid Brick

-

Concrete

-

Ceramic Hollow Block

-

Silicate Blocks

Applications

- Installation of plasterboards and OSB boards for walls and floors

- For bonding expanded polystyrene boards (EPS), extruded polystyrene boards (XPS) and polyurethane rigid foam boards (PUR)

- Insulation of containters or garages

- Filling gaps in thermal insulation

- Fastening of ceramic blocks, aerated concrete blocks and silicate blocks

- Installation of window sills and stairs

- For bonding decorative elements, coffers, floor moldings

Installation guide

- Wear protective gloves. Ensure surfaces are free from dust, dirt, lime or grease. If the wall surface is dirty it must be primed.

- Before using, make sure that the can temperature is above zero (optimum +20°C). Application temperature from +5°C up to +30°C.

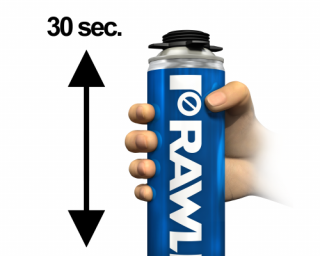

- Shake can vigorously for 30 seconds to mix properly components.

- Screw gun onto the can. Hold can upside-down during application.

- Moisten surfaces with water prior to application.

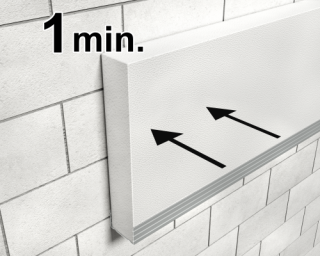

- Fill gaps from down to up, zigzag motion, alternating from one wall to the other. Fill gaps to approximately 60 % volume. Max. wide of the gap 3-4 cm. Wider gaps should be applied after hardening of the previous layer. Each layer should be moistened with water using a spray.

- After full curing, cut the excess foam with a knife and protect it from UV exposure by coating with plaster, paint, acrylic or silicone.

- In the event of a stoppage exceeding five minutes duration, wipe the nozzle with cleaner for foam applicator.

- After removing the applicator gun from the can, wipe down the nozzle and gun (internal and external surfaces) using a cleaner.