RPP-FIX Polyurethane Adhesive

Polyurethane adhesive with applicator gun, designed for bonding AQUA EPS and EPS boards for the insulation of facades and foundations.

Features and benefits

- Fixing possible just two hours after application.

- One product for thermal insulation of facades (EPS) and foundations (XPS).

- Highly efficient - coverage of about 8m2 facades and approx 12m2 foundations.

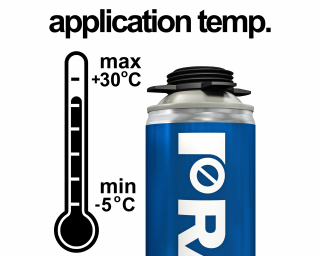

- Possible application at -5 ° C which significantly prolongs the construction season

- Portable - no requirement for access to water and electricity.

- High strength characteristics and excellent adhesion to common construction materials

Base material

-

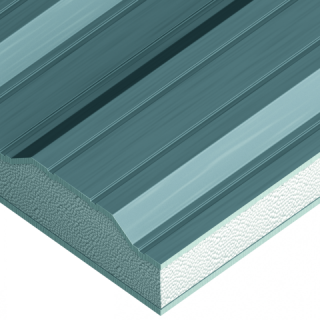

XPS Extruded Polystyrene Insulation Boards

-

boards_WebRes.png)

Polystyrene (EPS) Boards

For use also with

-

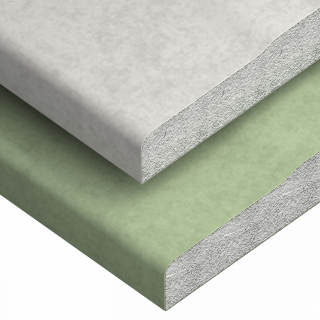

Gypsum Fibreboards

-

Plasterboard

-

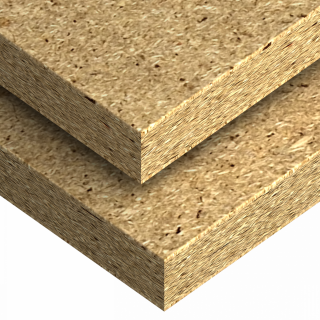

Chipboard

-

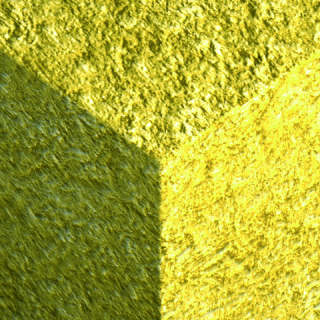

Mineral Wool Boards

-

Plywood

-

Sandwich Pannel

-

Non-plastered, Pressure-resistant Insulation Boards

Applications

- For bonding expanded polystyrene boards (EPS) on facade installations

- For bonding extruded polystyrene (XPS) on building foundations

- For bonding expanded polystyrene insulation

- For bonding and insulation of wall panels, corrugated sheets, roof tiles, etc.

- Suitable for fixing styrofoam boards in thermal insulation of buildings in the systems ETICS with mechanical fixings

- Filling gaps in the thermal insulation of buildings

- For fixing various types of insulation boards

Installation guide

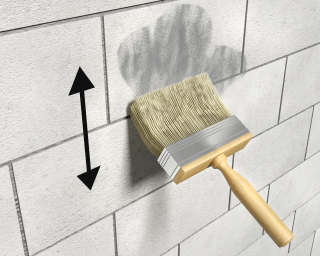

- Wear protective gloves. Ensure surfaces are free from dust, dirt, lime or grease. If the wall surface is dirty it must be primed.

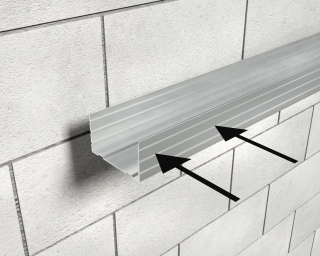

- Before adhering polystyrene board, starter track must be installed. Shake can vigorously for 30 seconds to mix properly components.

- Optimal can temperature is +20°C. Application temperature from -5°C up to +30°C. Screw gun onto the can. Hold can upside-down during application.

- For adhesion of foamed polystyrene facade insulation, apply a braid of Styrofix (approx. 3 cm wide) around the perimeter of polystyrene boards (approx. 2 cm from the edge), with an additional strip across the centre of the board.

- For adhesion of extruded polystyrene foam (XPS) on foundations, apply Styrofix in 4 vertical braids (approx. 3 cm wide) maintaining equal spacing of 20-30 cm between the strips. Ensure 3 cm clearance from the edge of the board (for boards wider than 100 cm, more braids should be applied).

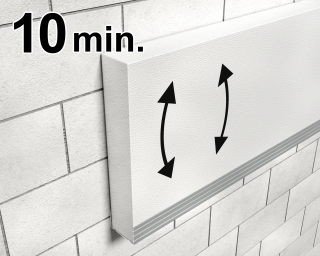

- Allow max. 5 minutes after application of Styrofix before mounting insulation to the facade or foundation. After mounting, adjust board to the desired position. Board adjustment is only possible for up to 10 minutes after adhesion. In the case of detachment from the surface apply again Styrofix.

- At lintels and in the corners, support the boards (approx. 10-15 min) until the bond cures. After 2 h the boards should be polished with an abrasive paper and additionally fixed with special mechanical connectors. Fill gaps between boards using Styrofix. When fully cured, the excess of adhesive should be removed mechanically (eg. using a knife).

- After removing the applicator gun from the can, wipe down the nozzle and gun (internal and external surfaces) using a cleaner.