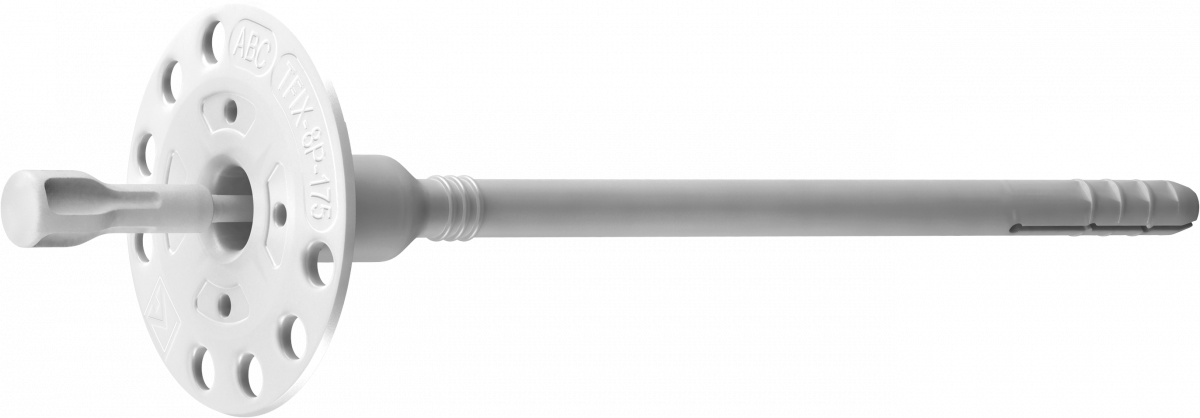

TFIX-8P Facade fixing with plastic pin

Versatile hammer-in facade fixing with plastic nail recommended for ETICS

Features and benefits

- Installation in all base materials (categories A,B,C,D,E)

- The plastic nail reduces heat transmission (value 0.0W/K)

- Pre-assembled expansion nail saves time and labour.

- Unique nylon pin design reinforced with glass fibre allows fast and trouble-free installation with correct expansion of the plug.

- Expansion zone designed for low embedment depths, reducing the amount of drilling required.

- Can be used in combination with additional KWL plate - 90, 110 or 140mm diameter.

Product information

Size |

Product Code |

Fixing |

Fixture |

|||

Diameter |

Length |

Plate diameter |

Recommended thickness |

|||

d |

L |

D |

tfix A, B, C, D |

tfix E |

||

[mm] | ||||||

Ø8 |

TFIX-8P-115-2 |

8 |

115 |

60 |

80 |

40 |

TFIX-8P-135-2 |

8 |

135 |

60 |

100 |

60 |

|

TFIX-8P-155-2 |

8 |

155 |

60 |

120 |

80 |

|

TFIX-8P-175-2 |

8 |

175 |

60 |

140 |

100 |

|

TFIX-8P-195-2 |

8 |

195 |

60 |

160 |

120 |

|

TFIX-8P-215-2 |

8 |

215 |

60 |

180 |

140 |

|

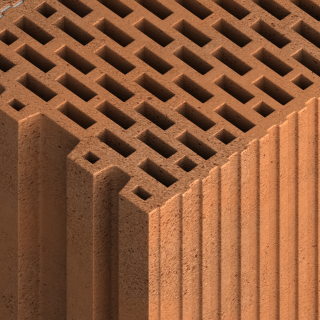

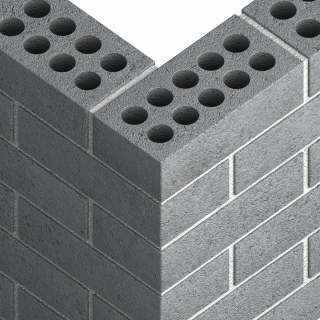

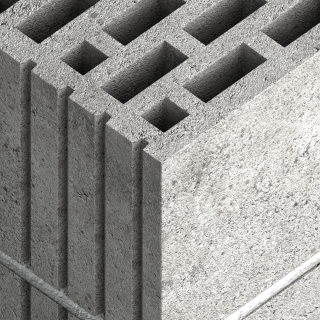

Base material

-

Concrete C12/15-C50/60 (Use category A)

-

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

Hollow Brick (Use category C)

-

Vertically-perforated clay block (Use category C)

-

Hollow Sand-lime Brick (Use category C)

-

Hollow Lightweight Concrete Block (Use category D)

-

Lightweight Concrete Block (Use category C)

-

.png)

Reinforced components of lightweight aggregate concrete (Use category D)

-

Aerated Concrete Block (Use category D)

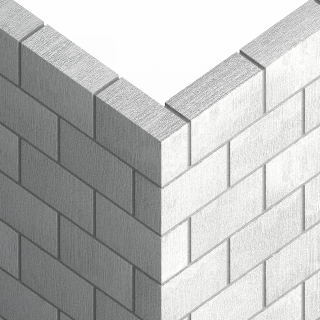

Applications

- External Thermal Insulation Composite Systems (ETICS)

- Polystyrene (EPS) boards

- Polyurethane (PU) boards

- Mineral wool (MW) boards

- Lightweight wood wool building boards

- Cork boards

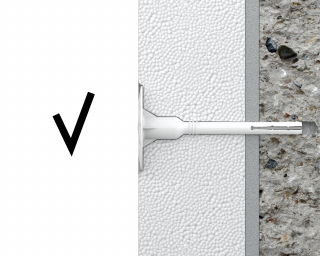

Installation guide

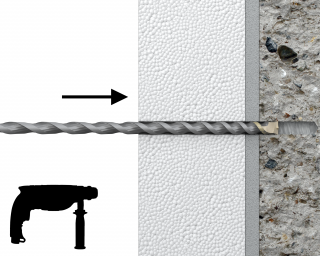

- Drill a hole of required diameter and depth

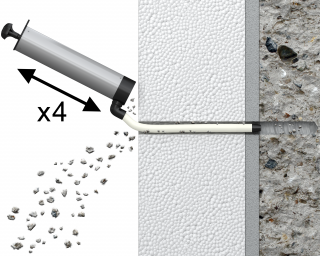

- Clean the hole

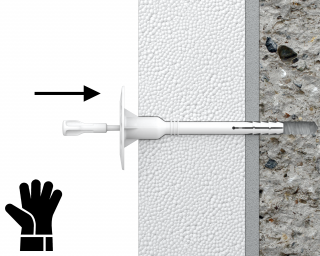

- Bottom side of the plate must be flush with the ETICS.

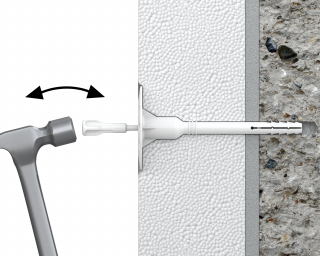

- Lightly tap the plastic nail into the plastic sleeve until fixing is secure and flush with insulation material.

- Embedment depth of min 25 in masonry, perforated materials and lightweight concrete blocks and 65mm in aerated concrete.

- In soft insulation panels the fixing should be combined with insulation retaining plates KWL-90, KWL-110, KWL-140.

Installation data

Substrate |

A, B, C, D |

E |

||

Hole diameter in substrate |

d0 |

[mm] |

8 |

8 |

Min. hole depth in substrate |

h0 |

[mm] |

40 |

80 |

Min. installation depth |

hnom |

[mm] |

25 |

65 |

Min. substrate thickness |

hmin |

[mm] |

100 |

110 |

Min. spacing |

smin |

[mm] |

100 |

100 |

Min. edge distance |

cmin |

[mm] |

100 |

100 |

Fixing diameter |

d |

[mm] |

8 |

8 |

Downloads

- TFIX-8P Facade fixing with plastic pin - Technical Data Sheet

- EC Certificate_2018 - TFIX-8P_EN.pdf

- ETAS 13-0845 TFIX-8P_ EN.pdf

- UKTA_TFIX-8P_0836-22_6340_2022_EN.pdf

Need documents for other product? Visit our Technical Library.

go to library